AdBlue Warning Light On (Fixed)

.jpg)

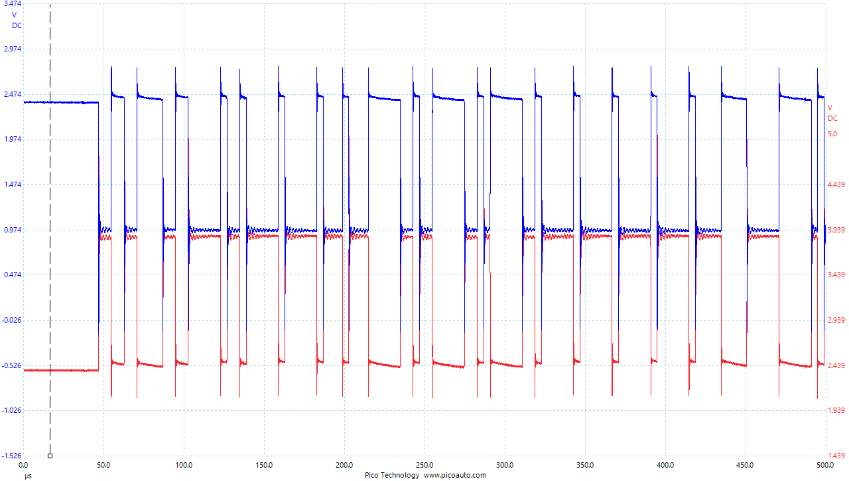

Volvo FL AdBlue Fault A Volvo truck was presented to our workshop today, the driver had reported a fault that the instrument cluster was showing a warning for AdBlue system failure. Naturally the first action to take was to carry out a diagnostic code read. However when we attempted to code read the AdBlue control module (ECU) it was found to be not communicating. Instead carrying out a fault code read of the engine control unit was found to be useful, here are the results: MID(128):Injection ECU, PSID:229, FMI (9):Data update frequency Connection problem with the UDS (AdBlue pump module) ECU on the SAE J1939 CAN bus data line. It became apparent that the AdBlue system was not accessible due to a CAN bus fault. The next step was to monitor the CAN network at the AdBlue ECU. As we explained in our previous CAN fault finding article , we first test the CAN network with the wiring block disconnected from the AdBlue ECU. The oscilloscope was ...